Pictures

click on a thumbnail to enlarge:

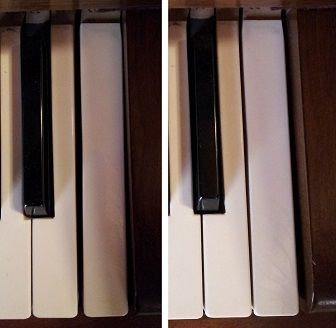

Broken agraffe; removed broken threaded section with reverse-thread-screw-extractor; replaced agraffe.

Major pin-block repair: it was splitting and the harp/plate hadn't cracked yet so was repairable. Top right is the only one I got during the process (I was kinda focused.) The other three corners are before & after shots. :-D

1) hammers not falling with gravity because of friction from shrinking/swelling wood compressing felt bushing 2) using a tool to push the hinge pin out 3) showing the hinge pin pushed out 4) showing a place the felt popped out with the pin 5) pulling new felt through hole. 6) after cutting felt flush with hole 7) filing & smoothing new felt 8 ) pushing in new pin 9) showing new pin in place 10) pin after clipped to correct length ALL DONE!

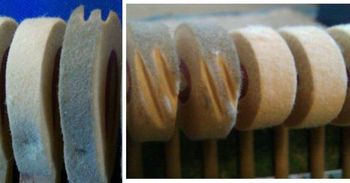

1) missing pins 2) start new pins with hammer & punch 3) screw in pins the rest of the way with tuning wrench short of 3.5 turns to allow for new wire coils 4) set new wire in place & make beckets (the 90 degree angled ends) 5) make sure wire is on hitch pin, through felt, and on bridge pins 6) screw on wire & use coil lifter to keep coils tight 7) all done

1&2 - drawing angled lines to make leg wedges/braces 3 - after the cut 4 - outside of leg wedge in place 5 - putting inner wedge in place 6 - hand tight 7 - hammered in 8 - third leg was curved so had to make a curved wedge on the spot

Top left: Leg off piano showing bracket. Bottom left: not-my-work-failed-electrical-tape-stripped-screw-repair. Right: Supporting the piano while I work on the leg.

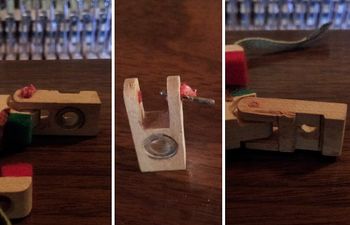

I've posted pictures of replacing bushings, but sometimes it's easier to replace the whole flange. Pictured is the original flange with the torn bushing, what it looked like after I removed it, and the new flange.